Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

This forum is in permanent archive mode. Our new active community can be found here.

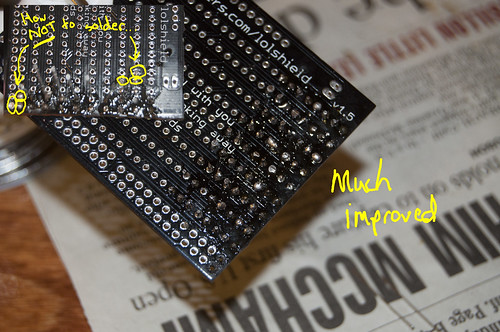

How not to solder.

After having my life taken over by work and family obligations for months, I finally had a free Saturday to work on an Arduino project. It's the LoL Board. When it's finished, it will be kind of fun to play with. However, the soldering requirements are brutal. My soldering skills were non-existent so taking on this exercise has really helped. As you can see by the picture, I'm making progress. When I first started, I managed to fill a half a dozen holes with solder that needed to remain open. I don't know if you have ever tried to de-solder, but it is a gigantic pain in the ass. Soldering itself is a smelly, time consuming affair. Yet, soldiering, learning electronics and figuring out my way around a multi-meter has been a very satisfying experience. It makes you look at gadgets differently. I'm starting to look at old electronics lying around the house as part sources for future projects.

When the Thing-o-Matic finally gets here, I'll be ready for it.

Comments

Also, desoldering is very easy with a solder wick. If you don't have any wick, get some right away. It's basically a copper braid that sucks up solder. Just heat the solder and put the wick near it, and it will suck it all right up. Then just cut off the end of the wick that is all soldered up.

Remember, soldering should be very quick and precise. Make sure the iron is very hot. I usually put mine at or close to the hottest available setting. Put your component through the hole. Bring the iron in to touch the pad (the metal ring around the hole) and the component simultaneously. Both need to be hot so the solder chemically bonds with both. Should only take a second or two to heat up. Bring in the solder and remove once you have enough, but before there's too much. Then remove the iron. Make sure to clean the iron with the wet sponge.

http://www.adafruit.com/index.php?main_page=product_info&cPath;=8&products;_id=151&zenid;=777b349ae9102d415f0c357e8c1c4bd4